A switched-mode power supply (switching-mode power supply, SMPS, or switcher) is an electronic power supply that incorporates a switching regulator to convert electrical power efficiently. Like other power supplies, an SMPS transfers power from a source, like mains power, to a load, such as a personal computer, while converting voltage and current

characteristics. An SMPS is usually employed to efficiently provide a

regulated output voltage, typically at a level different from the input

voltage.

Unlike a linear power supply, the pass transistor of a switching-mode supply continually switches between low-dissipation,

full-on and full-off states, and spends very little time in the high

dissipation transitions (which minimizes wasted energy). Ideally, a

switched-mode power supply dissipates no power. Voltage regulation

is achieved by varying the ratio of on-to-off time. In contrast, a

linear power supply regulates the output voltage by continually

dissipating power in the pass transistor.

This higher power conversion efficiency is an important advantage of a

switched-mode power supply. Switched-mode power supplies may also be

substantially smaller and lighter than a linear supply due to the

smaller transformer size and weight.

Switching regulators are used as replacements for the linear

regulators when higher efficiency, smaller size or lighter weight are

required. They are, however, more complicated; their switching currents

can cause electrical noise problems if not carefully suppressed, and

simple designs may have a poor power factor.

History

1926: "Electrical condensors" by Coursey

mentions high frequency welding

and furnaces.

1959: Transistor oscillation and rectifying converter power supply system

U.S. Patent 3,040,271 is filed.

1970: High-Efficiency Power Supply produced from about 1970 to 1995.

1972: HP-35, Hewlett-Packard's first pocket calculator, is introduced with transistor switching power supply for light-emitting diodes, clocks, timing, ROM, and registers.

1976: "Switched mode power supply"

U.S. Patent 4,097,773 is filed

1977: Apple II is designed with a switching mode power supply. "

For its time (1977) it was a breakthrough, since until then switching mode power supplies weren’t used. Designed by Rod Holt,".

"

Rod

Holt was brought in as product engineer and there were several flaws in

Apple II that were never publicized. One thing Holt has to his credit

is that he created the switching power supply that allowed us to do a

very lightweight computer".

1980: The HP8662A

10 kHz – 1.28 GHz synthesized signal generator went with a switched power supply.

Explanation

A linear regulator provides the desired output voltage by dissipating excess power in ohmic losses

(e.g., in a resistor or in the collector–emitter region of a pass

transistor in its active mode). A linear regulator regulates either

output voltage or current by dissipating the excess electric power in

the form of heat,

and hence its maximum power efficiency is voltage-out/voltage-in since

the volt difference is wasted. In contrast, a switched-mode power supply

regulates either output voltage or current by switching ideal storage

elements, like inductors and capacitors,

into and out of different electrical configurations. Ideal switching

elements (e.g., transistors operated outside of their active mode) have

no resistance when "closed" and carry no current when "open", and so the

converters can theoretically operate with 100% efficiency (i.e., all

input power is delivered to the load; no power is wasted as dissipated

heat).

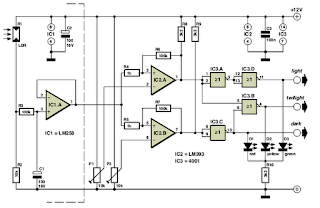

The basic schematic of a boost converter.

For example, if a DC source, an inductor, a switch, and the corresponding electrical ground are placed in series and the switch is driven by a square wave,

the peak-to-peak voltage of the waveform measured across the switch can

exceed the input voltage from the DC source. This is because the

inductor responds to changes in current by inducing its own voltage to

counter the change in current, and this voltage adds to the source

voltage while the switch is open. If a diode-and-capacitor combination

is placed in parallel to the switch, the peak voltage can be stored in

the capacitor, and the capacitor can be used as a DC source with an

output voltage greater than the DC voltage driving the circuit. This boost converter acts like a step-up transformer for DC signals. A buck–boost converter

works in a similar manner, but yields an output voltage which is

opposite in polarity to the input voltage. Other buck circuits exist to

boost the average output current with a reduction of voltage.

In an SMPS, the output current flow depends on the input power

signal, the storage elements and circuit topologies used, and also on

the pattern used (e.g., pulse-width modulation with an adjustable duty cycle) to drive the switching elements. Typically, the spectral density of these switching waveforms has energy concentrated at relatively high frequencies. As such, switching transients, like ripple, introduced onto the output waveforms can be filtered with small LC filters.

Advantages and disadvantages

The main advantage of this method is greater efficiency because the

switching transistor dissipates little power when it is outside of its

active region (i.e., when the transistor acts like a switch and either

has a negligible voltage drop across it or a negligible current through

it). Other advantages include smaller size and lighter weight (from the

elimination of low frequency transformers which have a high weight) and

lower heat generation due to higher efficiency. Disadvantages include

greater complexity, the generation of high-amplitude, high-frequency

energy that the low-pass filter must block to avoid electromagnetic interference (EMI), a ripple voltage at the switching frequency and the harmonic frequencies thereof.

Very low cost SMPSs may couple electrical switching noise back onto

the mains power line, causing interference with A/V equipment connected

to the same phase. Non-power-factor-corrected SMPSs also cause harmonic distortion.

Theory of operation

Input rectifier stage

If the SMPS has an AC input, then the first stage is to convert the input to DC. This is called rectification.

The rectifier circuit can be configured as a voltage doubler by the

addition of a switch operated either manually or automatically. This is a

feature of larger supplies to permit operation from nominally

120 V or

240 V

supplies. The rectifier produces an unregulated DC voltage which is

then sent to a large filter capacitor. The current drawn from the mains

supply by this rectifier circuit occurs in short pulses around the AC

voltage peaks. These pulses have significant high frequency energy which

reduces the power factor. Special control techniques can be employed by

the SMPS to force the average input current to follow the sinusoidal

shape of the AC input voltage, correcting the power factor. An SMPS with

a DC input does not require this stage. An SMPS designed for AC input

can often be run from a DC supply (for

230 V AC this would be

330 V DC),

as the DC passes through the rectifier stage unchanged. It's however

advisable to consult the manual before trying this, though most supplies

are quite capable of such operation even though nothing is mentioned in

the documentation. However, this type of use may be harmful to the

rectifier stage as it will only use half of diodes in the rectifier for

the full load. This may result in overheating of these components, and

cause them to fail prematurely.

If an input range switch is used, the rectifier stage is usually configured to operate as a voltage doubler when operating on the low voltage (

~120 V AC) range and as a straight rectifier when operating on the high voltage (

~240 V AC)

range. If an input range switch is not used, then a full-wave rectifier

is usually used and the downstream inverter stage is simply designed to

be flexible enough to accept the wide range of DC voltages that will be

produced by the rectifier stage. In higher-power SMPSs, some form of

automatic range switching may be used.

Inverter stage

The inverter stage converts DC, whether directly from the input or from

the rectifier stage described above, to AC by running it through a power

oscillator, whose output transformer is very small with few windings at

a frequency of tens or hundreds of kilohertz.

The frequency is usually chosen to be above 20 kHz, to make it

inaudible to humans. The switching is implemented as a multistage (to

achieve high gain) MOSFET amplifier. MOSFETs are a type of transistor with a low on-resistance and a high current-handling capacity.

Voltage converter and output rectifier

If the output is required to be isolated from the input, as is

usually the case in mains power supplies, the inverted AC is used to

drive the primary winding of a high-frequency transformer.

This converts the voltage up or down to the required output level on

its secondary winding. The output transformer in the block diagram

serves this purpose.

If a DC output is required, the AC output from the transformer is

rectified. For output voltages above ten volts or so, ordinary silicon

diodes are commonly used. For lower voltages, Schottky diodes

are commonly used as the rectifier elements; they have the advantages

of faster recovery times than silicon diodes (allowing low-loss

operation at higher frequencies) and a lower voltage drop when

conducting. For even lower output voltages, MOSFETs may be used as synchronous rectifiers; compared to Schottky diodes, these have even lower conducting state voltage drops.

The rectified output is then smoothed by a filter consisting of inductors and capacitors. For higher switching frequencies, components with lower capacitance and inductance are needed.

Simpler, non-isolated power supplies contain an inductor instead of a transformer. This type includes boost converters, buck converters, and the buck-boost

converters.

These belong to the simplest class of single input, single output

converters which use one inductor and one active switch. The buck

converter reduces the input voltage in direct proportion to the ratio of

conductive time to the total switching period, called the duty cycle.

For example an ideal buck converter with a 10 V input operating at a 50%

duty cycle will produce an average output voltage of 5 V. A feedback

control loop is employed to regulate the output voltage by varying the

duty cycle to compensate for variations in input voltage. The output

voltage of a boost converter

is always greater than the input voltage and the buck-boost output

voltage is inverted but can be greater than, equal to, or less than the

magnitude of its input voltage. There are many variations and extensions

to this class of converters but these three form the basis of almost

all isolated and non-isolated DC to DC converters. By adding a second

inductor the Ćuk and SEPIC converters can be implemented, or, by adding additional active switches, various bridge converters can be realised.

Other types of SMPSs use a capacitor-diode voltage multiplier instead of inductors and transformers. These are mostly used for generating high voltages at low currents . The low voltage variant is called charge pump.

Regulation

A feedback

circuit monitors the output voltage and compares it with a reference

voltage, which shown in the block diagram serves this purpose. Depending

on design/safety requirements, the controller may contain an isolation

mechanism (such as opto-couplers)

to isolate it from the DC output. Switching supplies in computers, TVs

and VCRs have these opto-couplers to tightly control the output voltage.

Open-loop regulators do not have a feedback circuit. Instead,

they rely on feeding a constant voltage to the input of the transformer

or inductor, and assume that the output will be correct. Regulated

designs compensate for the impedance of the transformer or coil. Monopolar designs also compensate for the magnetic hysteresis of the core.

The feedback circuit needs power to run before it can generate power,

so an additional non-switching power-supply for stand-by is added.

Transformer design

SMPS transformers run at high frequency. Most of the cost savings

(and space savings) in off-line power supplies result from the smaller

size of high frequency transformer compared to the 50/60 Hz transformers

formerly used. There are additional design tradeoffs.

The terminal voltage of a transformer is proportional to the product

of the core area, magnetic flux, and frequency. By using a much higher

frequency, the core area (and so the mass of the core) can be greatly

reduced.

However, higher frequency also means more energy lost during

transitions of the switching semiconductor. Furthermore, more attention

to the physical layout of the circuit board is required, and the amount of electromagnetic interference will be more pronounced.

Core losses increase at higher frequencies. Cores use ferrite

material which has a low loss at the high frequencies and high flux

densities used. The laminated iron cores of lower-frequency (<400 Hz)

transformers would be unacceptably lossy at switching frequencies of a

few kilohertz.

Copper loss

Main article: Copper loss

At low frequencies (such as the line frequency of 50 or 60 Hz), designers can usually ignore the skin effect.

For these frequencies, the skin effect is only significant when the

conductors are large, more than 0.3 inches (7.6 mm) in diameter.

Switching power supplies must pay more attention to the skin effect

because it is a source of power loss. At 500 kHz, the skin depth in

copper is about 0.003 inches (0.076 mm) – a dimension smaller than the

typical wires used in a power supply. The effective resistance of

conductors increases, because current concentrates near the surface of

the conductor and the inner portion carries less current than at low

frequencies.

The skin effect is exacerbated by the harmonics present in the high speed PWM

switching waveforms. The appropriate skin depth is not just the depth

at the fundamental, but also the skin depths at the harmonics.

In addition to the skin effect, there is also a proximity effect, which is another source of power loss.

Power factor

Simple off-line switched mode power supplies incorporate a simple

full-wave rectifier connected to a large energy storing capacitor. Such

SMPSs draw current from the AC line in short pulses when the mains

instantaneous voltage exceeds the voltage across this capacitor. During

the remaining portion of the AC cycle the capacitor provides energy to

the power supply.

As a result, the input current of such basic switched mode power supplies has high harmonic

content and relatively low power factor. This creates extra load on

utility lines, increases heating of building wiring, the utility transformers,

and standard AC electric motors, and may cause stability problems in

some applications such as in emergency generator systems or aircraft

generators. Harmonics can be removed by filtering, but the filters are

expensive. Unlike displacement power factor created by linear inductive

or capacitive loads, this distortion cannot be corrected by addition of a

single linear component. Additional circuits are required to counteract

the effect of the brief current pulses. Putting a current regulated

boost chopper stage after the off-line rectifier (to charge the storage

capacitor) can correct the power factor, but increases the complexity

and cost.

In 2001, the European Union put into effect the standard

IEC/EN61000-3-2 to set limits on the harmonics of the AC input current

up to the 40th harmonic for equipment above 75 W. The standard defines

four classes of equipment depending on its type and current waveform.

The most rigorous limits (class D) are established for personal

computers, computer monitors, and TV receivers. To comply with these

requirements, modern switched-mode power supplies normally include an

additional power factor correction (PFC) stage.

Efficiency and EMI

Higher input voltage and synchronous rectification mode makes the

conversion process more efficient. The power consumption of the

controller also has to be taken into account. Higher switching frequency

allows component sizes to be shrunk, but can produce more RFI. A resonant forward converter produces the lowest EMI of any SMPS approach because it uses a soft-switching resonant waveform compared with conventional hard switching.

Failure modes

Power supplies which use capacitors suffering from the capacitor plague

may experience premature failure when the capacitance drops to 4% of

the original value. This usually causes the switching semiconductor to

fail in a conductive way. That may expose connected loads to the full

input volt and current, and precipitate wild oscillations in output.

Failure of the switching transistor is common. Due to the large switching voltages this transistor must handle (around

325 V for a

230 VAC mains supply), these transistors often short out, in turn immediately blowing the main internal power fuse.

Precautions

The main filter capacitor will often store up to

325 V

long after the power cord has been removed from the wall. Not all power

supplies contain a small "bleeder" resistor to slowly discharge this

capacitor. Any contact with this capacitor may result in a severe

electrical shock.

The primary and secondary side may be connected with a capacitor to reduce EMI

and compensate for various capacitive couplings in the converter

ciruit, where the transformer is one. This may result in electric shock

in some cases. The current flowing from line or neutral through a

2000 Ω resistor to any accessible

part must according to

IEC 60950 be less than

250 μA for IT equipment.

Applications

Switched-mode power supply units (PSUs) in domestic products such as personal computers often have universal inputs, meaning that they can accept power from mains supplies

throughout the world, although a manual voltage range switch may be

required. Switch-mode power supplies can tolerate a wide range of power frequencies and voltages.

In 2006, at an Intel

Developers Forum, Google engineers proposed the use of a single 12 V

supply inside PCs, due to the high efficiency of switch mode supplies

directly on the PCB.

Due to their high volumes mobile phone chargers have always been particularly cost sensitive. The first chargers were linear power supplies

but they quickly moved to the cost effective ringing choke converter

(RCC) SMPS topology, when new levels of efficiency were required.

Recently, the demand for even lower no load power requirements in the

application has meant that flyback topology is being used more widely;

primary side sensing flyback controllers are also helping to cut the bill of materials (BOM) by removing secondary-side sensing components such as optocouplers.

Switched-mode power supplies are used for DC to DC conversion as well. In automobiles where heavy vehicles use a nominal

24 VDC

cranking supply, 12 volts for accessories may be furnished through a

DC/DC switch-mode supply. This has the advantage over tapping the

battery at the 12 volt position that all the 12 Volt load is evenly

divided over all cells of the 24 volt battery. In industrial settings

such as telecommunications racks, bulk power may be distributed at a low

DC voltage (from a battery back up system, for example) and individual

equipment items will have DC/DC switched-mode converters to supply

whatever voltages are needed.